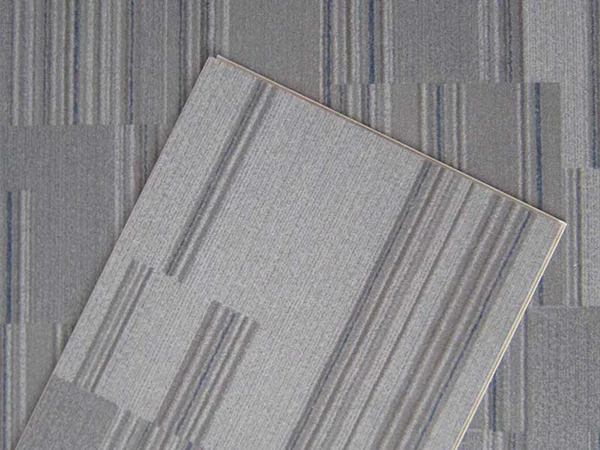

SPC flooring is a hard floor made of limestone powder, PVC and stabilizers, popular for its durability and water-resistant properties. Its surface can be embossed to create a variety of textures, enhancing quality and visual appeal. Here are the key details about the embossing treatment of SPC flooring.

During the production of SPC flooring, after the wear layer is applied, a textured embossing plate is typically pressed onto the surface. Through a hot-pressing process, the desired three-dimensional texture is formed. This technique is designed to replicate the appearance of natural materials such as wood grain and stone, enhancing the visual appeal and realistic feel of the flooring.

| Item | Register Embossing | Embossed Surface | Hand-Scraped Embossing | Textured Embossing | Deep Embossing |

|---|---|---|---|---|---|

| Process | Advanced technology is used to ensure that the embossing is perfectly aligned with the pattern layer. | The texture pattern is embossed directly without specific alignment. | Simulates hand-scratching effects to create irregular textures. | Creates uniform, subtle textures on the surface. | Heat embossing on the surface of SPC flooring by designing high-precision molds. |

| Features | Extremely realistic, enhances the sense of depth, suitable for high-end flooring products. | Highly versatile, the texture adds visual interest. | Textured surfaces help hide scratches and wear that occur over time. | Elegant look and enhanced tactile experience. | Similar to natural wood grain, it provides depth and dimension, suitable for rustic style decoration. |

| Applications | Used in living rooms, dining rooms and retail spaces. | Suitable for casual or rustic designs. | For traditional or vintage-style homes. | Suitable for modern and contemporary spaces. | Applied to outdoor spaces, commercial spaces. |

The embossed design of SPC flooring is both beautiful and practical, and is very popular. Its various textures and gloss levels meet different design needs and perform well in high-traffic areas. Mastering various embossing processes and their performance characteristics enables informed selection tailored to spatial aesthetics and functional requirements. For more information, please feel free to contact us!