Optimizing Flame Retardancy and Strength in WPC

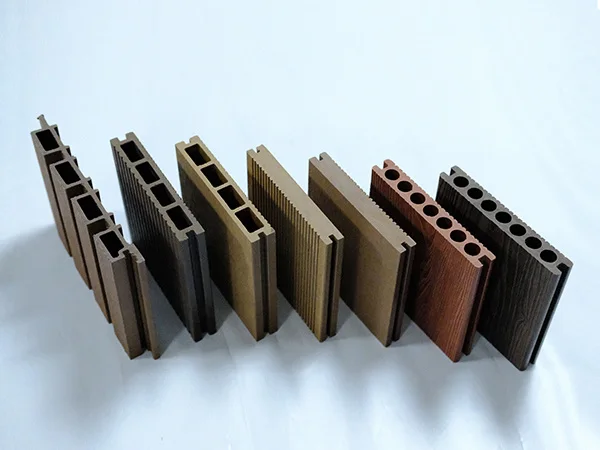

WPC (wood plastic composite) is an eco-friendly material composed of wood fibers and thermoplastics (e.g., polyethylene or polypropylene). It combines the natural appearance of wood with the advantages of plastics, including corrosion resistance, machinability, and recyclability, making it widely applicable in construction, furniture, gardening, and other fields.

To meet higher performance demands, enhancing its flame retardancy, mechanical properties, and structural stability has become a key focus in its research and applications.

Flame Retardant Performance

- Flame retardant type: Commonly used in tumescent flame retardants (e.g. expandable graphite EG) expand rapidly at high temperatures to form a carbon layer, isolate heat sources and combustible gases, and inhibit combustion.

- Flame retardant mechanism: Flame retardants dehydrate and carbonize at high temperatures to form a porous carbon structure, reduce heat conduction and gas diffusion, and significantly improve flame retardant properties.

- Modification technology: Surface modification of inorganic flame retardants (e.g. magnesium hydroxide) to enhance their compatibility with the polymer matrix, thereby improving the flame retardant effect.

Mechanical Properties

- Introduction of reinforcing agent: Adding nano-silicon dioxide (n-SiO2) can significantly improve the strength and stiffness of WPC. An appropriate amount (like 5%) of n-SiO2 can improve the mechanical properties by 15% – 30%.

- Interface compatibility: Use self-assembled polyethyleneimine (PEI) and cellulose nanocrystals (CNC) to enhance the compatibility of wood fiber and plastic matrix and improve the overall mechanical properties.

Structural design

- Multilayer sandwich structure: The multilayer structure with surface flame retardant and core reinforcement can improve the flame retardant performance while maintaining the strength and stability of the material, expanding its application potential.

Application Prospects

Wood-plastic composites (WPC) are achieving performance breakthroughs through flame retardancy, reinforcement, and structural design innovations. Leveraging their eco-friendly and recyclable advantages, WPC is poised to play an increasingly vital role in sustainable building materials and other green applications.