Expansion Joints for SPC Flooring: Avoid Warping, Noise, and Deformation

When installing SPC flooring, proper expansion joints play a crucial role in long-term durability and aesthetic appeal. These small gaps, left between floor panels, along walls, and at connections, allow SPC flooring to expand and contract naturally with changes in temperature and humidity, preventing damage and maintaining floor stability.

Why Expansion Joints Matter

Expansion joints are the small gaps left between floor panels, along walls, and at connections during installation. Since SPC material expands and contracts with temperature and humidity changes, these gaps provide “breathing room,” allowing the floor to move freely without being squeezed.

Insufficient Gaps May Cause:

- Warping or deformation of the flooring.

- Unusual noises from internal stress.

- Reduced aesthetics and compromised user experience.

Factors Affecting SPC Floor Expansion

- Temperature: Heat, underfloor heating, or sunlight can expand the floor.

- Humidity: Moisture absorption in damp environments causes expansion.

- Installation: Uneven gaps or missing spacers affect expansion.

How to Ensure Proper Expansion Gaps in SPC Flooring Installation

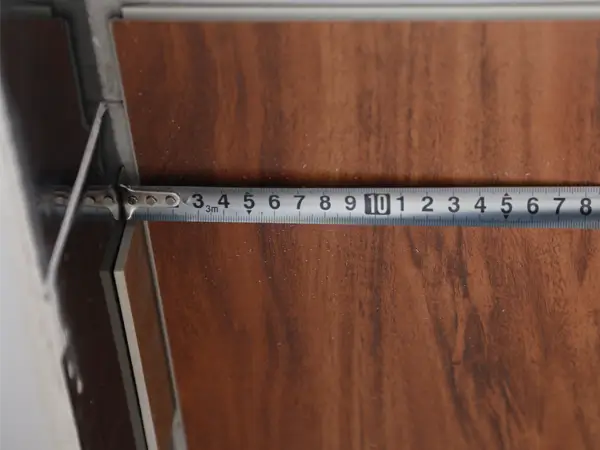

- Standardized Expansion Gaps

- Leave a 1–2 mm gap between the flooring and walls.

- For large areas, install expansion joints every 5–8 meters.

- Use Tools Properly

- Use specialized shims and a straightedge to ensure consistent gaps.

- Environmental Preconditioning

- Allow the flooring to acclimate to the room for 24–48 hours before installation.

- Choose Quality Materials

- High-quality SPC flooring should have excellent dimensional stability and resistance to moisture and heat.

Although often overlooked, expansion gaps in SPC flooring are essential for long-term durability and stability. Correct spacing, proper installation techniques, and quality materials help prevent warping, noise, and aesthetic issues, ensuring the floor performs and looks its best.